The pulp and paper industry requires a lot of fresh and process water for the various production stages. Consequently, for economical, as well as ecological reasons, the industry is interested in treating wastewater as efficient as possible and reusing as much process water as possible in the closed process loop. The sludge obtained with valuable recyclables can be purposely reused and the residual sludge processed, with the lowest possible water content, for disposal.

Our approach

To meet those requirements is the original goal of MUST and its "Molecular Unique Separation Technology“. ECtop has specially been developed and promoted for industries for years, so that process water can be treated on site and thus optimally used in the cycle.

The ECtop process as a continuous electro-coagulation technology can purify the process water on site, which occurs at the production stage, directly in the flow and return it to the process. This enables very efficient and, if necessary, targeted decentralized cleaning and re-feeding into the circuit.

Benefits

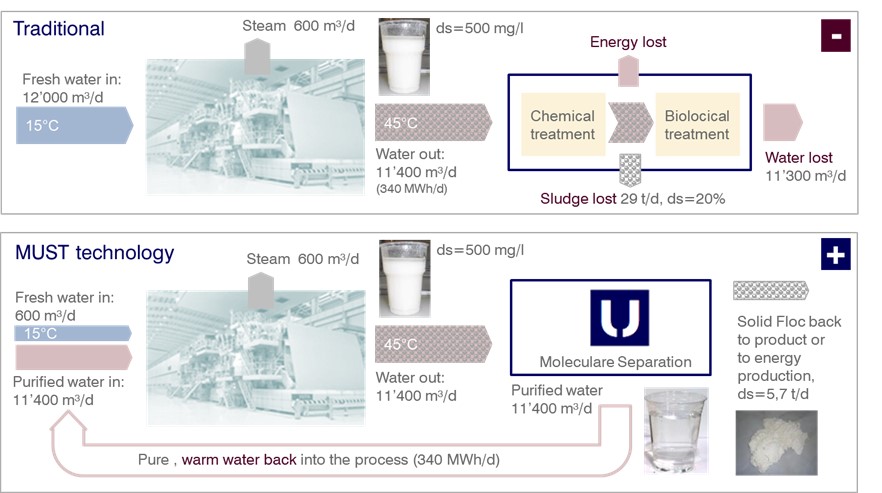

The MUST ECtop technology has a decisive advantage compared to conventional cleaning methods due to the possibility of direct cleaning of the process water, in the unchanged conditional state.

As an example, the following is a case study with the use of warm process water compared to conventional chemical and biological wastewater treatment. Besides efficient cleaning, there are substantial energy savings and the process water temperature is maintained.