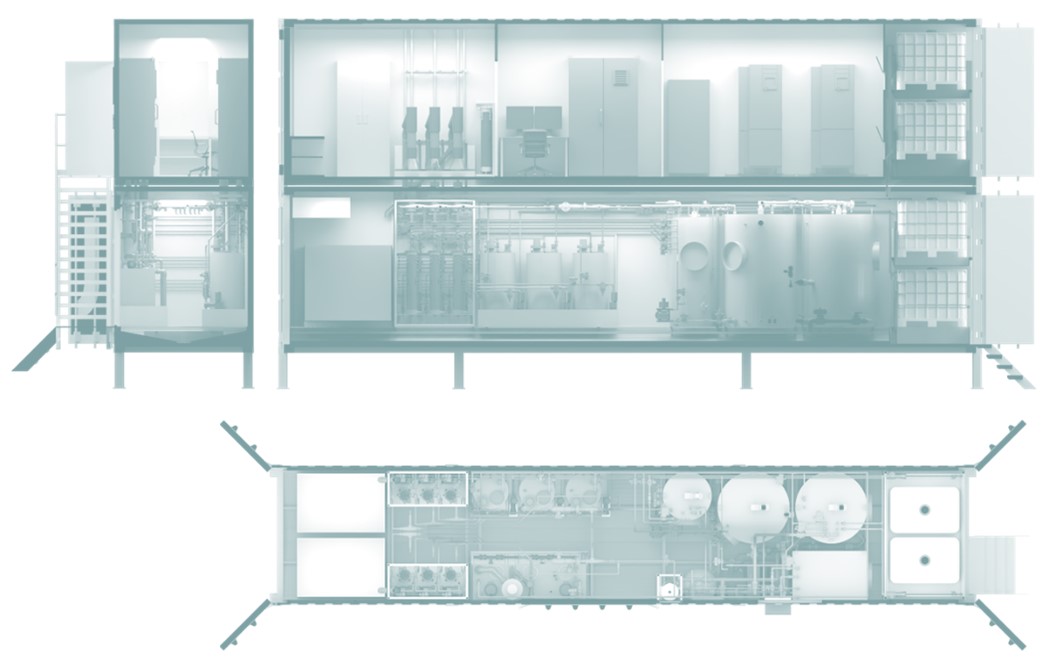

The MUST ECtop technology is a high effective wastewater treatment method for purifying difficult and demanding types of wastewater. The ECtop technology is a continuous electro-coagulation method, which has been developed over several years with development partners and universities as research partners. The focus of the technology is on wastewater, which contains dissolved impurities that are difficult to precipitate and which can be efficiently treated in a process loop for reuse. For this purpose, a method has been developed that can be integrated directly into the process water stream as a continuous treatment unit and can carry out the purification continously. The process is based on the proven electro-coagulation and uses its chemical-physical advantages for an efficient separation of mostly dissolved or colloidal impurities. The method is space-saving due to its compact design and can be set up and operated on site. This in form of containerized units or as a permanently integrated system.

The ECtop method is based on a proven electro-coagulation technology, which has been further developed into the coaxial continuous run-through-process. This continuous method is a highly reliable and well efficient wastewater treatment technology.

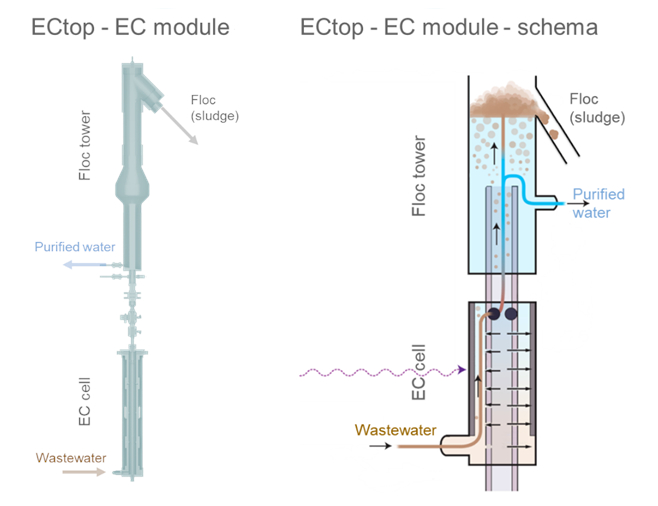

The cleaning method mainly relies on using electrical power to accurately ionize the wastewater stream and provoke the direct coagulation of the impurities. The method can be divided into 4 main streams. The inflow of wastewater, the applying of direct current and on the output side of the method the purified water and the resulting impurities as floc (sludge with a low water content).

The main component of the ECtop method is the EC module, in which the purification takes place. The module is divided into an EC cell and a floc tower. The EC cell is a coaxial unit where, by applying direct current, the dissolved or colloidal particles are flocculated directly in the flow of the wastewater. The flocculation is achieved through the dissolving and applying ions, which can be of different types, depending on the wastewater and its impurities. In addition, the advantage of the vertical designed method and the function as a small electrolysis unit, are used in a targeted manner. Here, a tiny quantity of hydrogen is generated, which combines with the coagulated impurities and are caused to float as sludge or herewith so-called floc. The cleaned wastewater is discharge by using the siphon effect and the floc is geodetically extracted. The form of this purification method provides a positive self-drying effect to the floc, which allows the reduction of the water content in the floc / sludge furthermore.